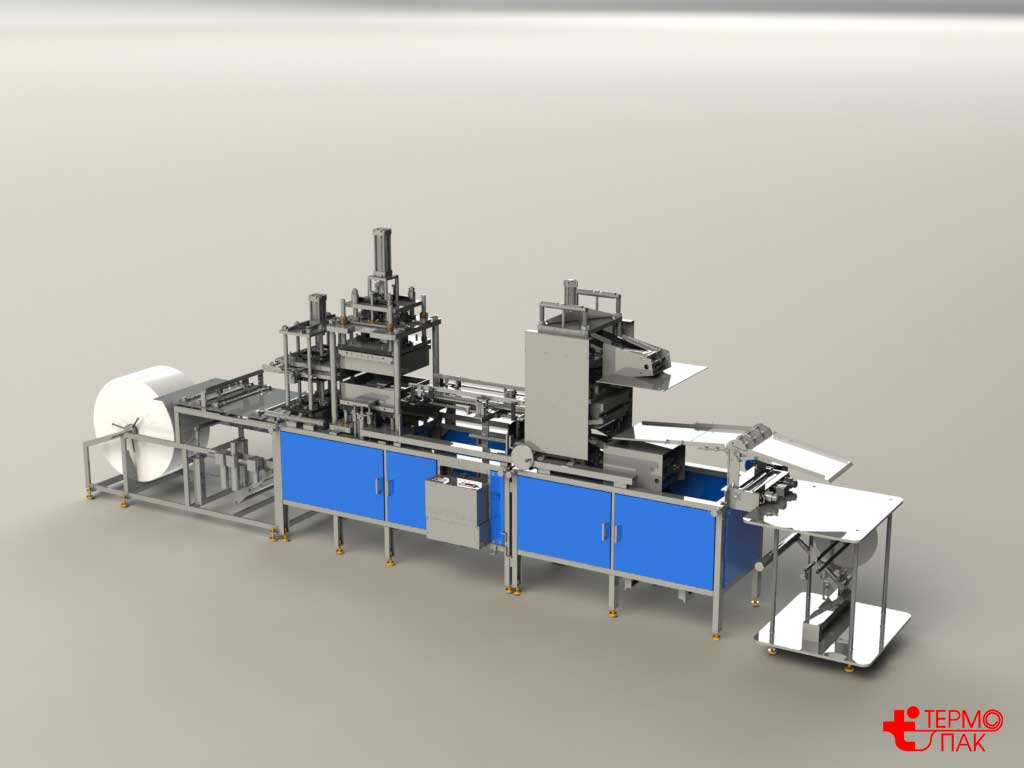

MAT-300PN Diapazon makes the manufacturing of the sophisticated blister package simple!

MAT-300PN Diapazon makes the manufacturing of the sophisticated blister package simple!

Forming and cutting technology is the same as GN Plastics from Canada.

Climatic performance in accordance with

|

УХЛ 4.2 |

Degree of protection: |

IP 3.0 |

Drive Type: |

pneumatic |

КClass purity of the compressed air in accordance with GOST 17433: |

not worse than 8 |

Power supply: |

380V, 3F |

Maximum power consumption: |

9,0 kW |

Average power consumption: |

6,0 kW |

Compressed air pressure: |

5,5 - 10 bar |

Maximum air consumption: |

3,0 m3/min |

Average (nominal) compressed air consumption: |

2,58 m3/min |

Type of coolant: |

Tap water, industrial water, antifreeze, glycol solutions (liquid or reusable with water cooler) |

Maximum consumption of coolant: |

10 l/min |

The method of heating the material: |

contact,two-sided |

Molding method: |

pneumatic with pre-extraction with punch |

Method for separating the products: |

Diversity cutting |

Types of manufactured products: |

negative, positive, negative and positive |

Maximum dimensions of manufactured products: |

350 × 450 mm |

Maximum depth of manufactured products: |

100 mm |

Plastics types: |

HIPS, SB, PVC, PET |

Plastics thickness: |

HIPS, SB, PVC: 0,15 - 0,7 mm

|

Maximum width of plastics: |

390 mm |

Maximum roll diameter of plastics: |

500 mm |

Maximum weight of a plastics roll: |

70 kg |

Performance: |

12 - 20 cycles/min |

Guaranteed load factor when changing tooling is not more than 1 time per week: |

0,91 |

Overall dimensions (length × width × height): |

5800 × 980 × 2200 mm |

Weight:: |

2100 kg |

Average changeover time: |

2,0 hours |

"We do it today, others will think about it only tomorrow" – here is a principle by which our company is guided since 1997. That’s why our equipment enjoys popularity not only among small and medium enterprises, but also among well-known large enterprises which have a continuous production process.