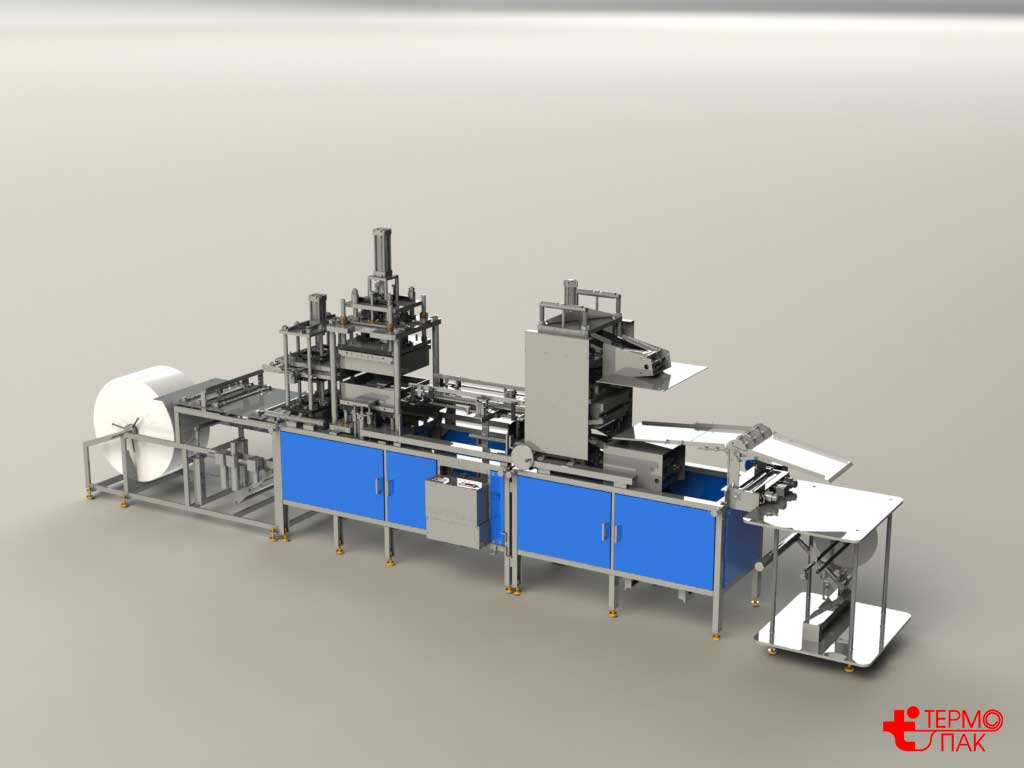

MAT-300PN Diapazon makes the manufacturing of the sophisticated blister package simple!

MAT-300PN Diapazon makes the manufacturing of the sophisticated blister package simple!

Forming and cutting technology is the same as GN Plastics from Canada.

Climatic performance in accordance with

|

УХЛ 4.2 |

Degree of protection: |

IP 3.0 |

Drive Type: |

pneumatic |

КClass purity of the compressed air in accordance with GOST 17433: |

not worse than 8 |

Power supply: |

380V, 3F |

Maximum power consumption: |

9,0 kW |

Average power consumption: |

6,0 kW |

Compressed air pressure: |

5,5 - 10 bar |

Maximum air consumption: |

3,0 m3/min |

Average (nominal) compressed air consumption: |

2,58 m3/min |

Type of coolant: |

Tap water, industrial water, antifreeze, glycol solutions (liquid or reusable with water cooler) |

Maximum consumption of coolant: |

10 l/min |

The method of heating the material: |

contact,two-sided |

Molding method: |

pneumatic with pre-extraction with punch |

Method for separating the products: |

Diversity cutting |

Types of manufactured products: |

negative, positive, negative and positive |

Maximum dimensions of manufactured products: |

350 × 450 mm |

Maximum depth of manufactured products: |

100 mm |

Plastics types: |

HIPS, SB, PVC, PET |

Plastics thickness: |

HIPS, SB, PVC: 0,15 - 0,7 mm

|

Maximum width of plastics: |

390 mm |

Maximum roll diameter of plastics: |

500 mm |

Maximum weight of a plastics roll: |

70 kg |

Performance: |

12 - 20 cycles/min |

Guaranteed load factor when changing tooling is not more than 1 time per week: |

0,91 |

Overall dimensions (length × width × height): |

5800 × 980 × 2200 mm |

Weight:: |

2100 kg |

Average changeover time: |

2,0 hours |

The reliability of our equipment is due to many years of experience on the market of thermoforming equipment and moulds, as well as the use of component parts of only well-known manufacturers.