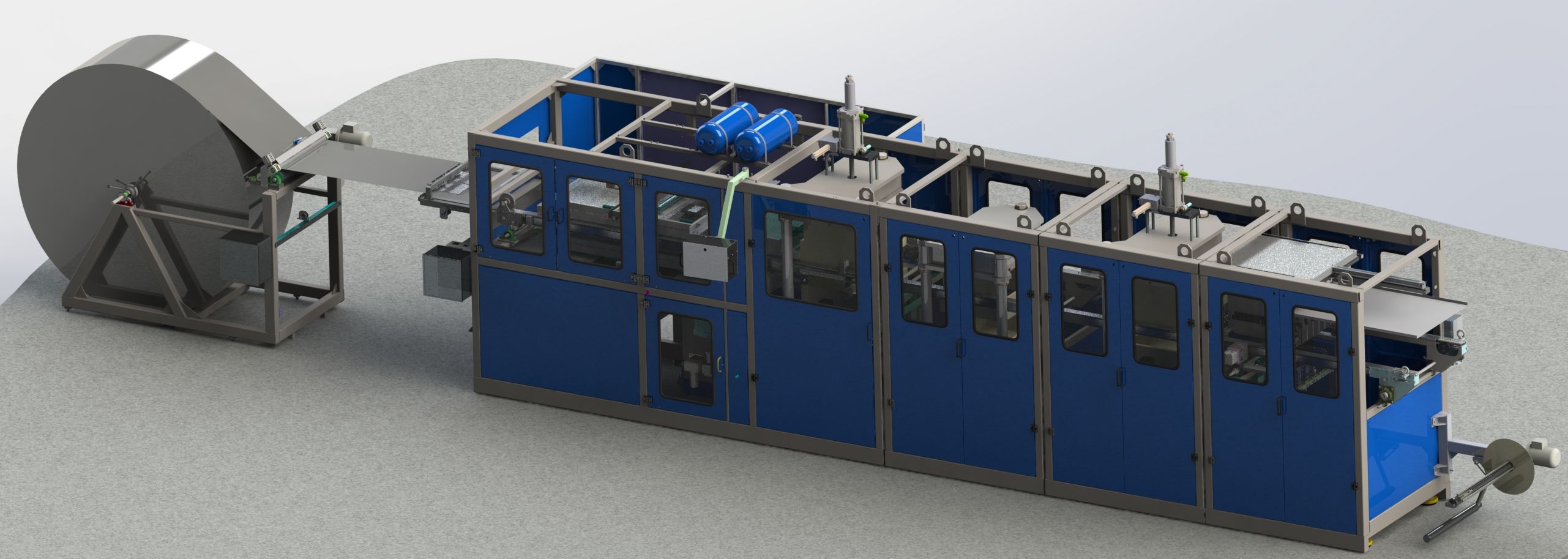

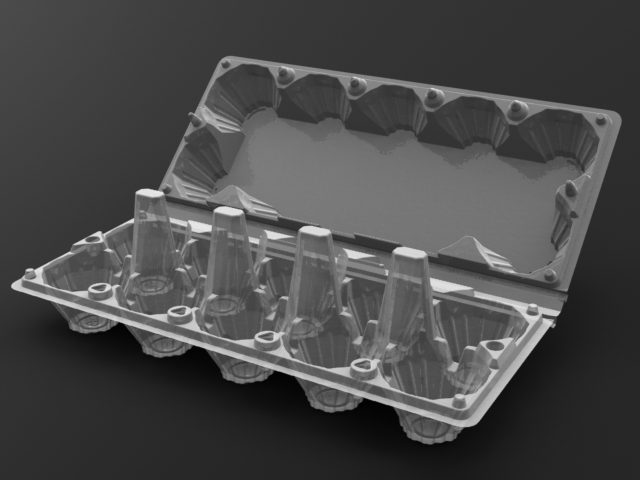

Purpose is producing of trays, cups, lids, cans, cups, correxes, lunch boxes and blister packaging.

Purpose is producing of trays, cups, lids, cans, cups, correxes, lunch boxes and blister packaging.

Climatic performance in accordance with

|

УХЛ 4.2 |

Degree of protection: |

IP 3.0 |

Drive Type: |

pneumatic |

КClass purity of the compressed air in accordance with GOST 17433: |

not worse than8 |

Power supply: |

380V, 3F |

Maximum power consumption: |

85,0 kW |

Average power consumption: |

20,0 kW |

Compressed air pressure: |

6 - 10 bar |

Maximum air consumption: |

2,55 m3/min |

Average (nominal) compressed air consumption: |

2,28 m3/min |

Type of coolant: |

Multiturn water cooler |

Maximum consumption of coolant: |

50 l/min |

The method of heating the material: |

non-contact,two-sided |

Molding method: |

pneumatic with pre-extraction with punch |

Method for separating the products: |

combined or diversed cutting tools with stacking |

Types of manufactured products: |

negative, positive, negative and positive |

Maximum dimensions of manufactured products: |

550 × 510 mm |

Maximum depth of manufactured products: |

130 mm |

Plastics types: |

HIPS, SB, OPS, PVC, PET, PP |

Plastics thickness: |

0,18 - 1,5 mm |

Maximum width of plastics: |

610 mm |

Maximum roll diameter of plastics: |

1800 mm |

Maximum weight of a plastics roll: |

800 kg |

Performance: |

12 - 35 cycles/min |

Guaranteed load factor when changing tooling is not more than 1 time per week: |

0,91 |

Overall dimensions (length × width × height): |

8000 × 2500 × 2500 mm |

Weight:: |

3800 kg |

Average changeover time: |

2,0 hours |

One of the basic principles of our work is to meet as much as possible the demands of our customers, to be attentive to them during the whole operating period of the supplied equipment. Our customer relationship is not limited to a warranty period.